Hydrogels

Optimized GelMA Hydrogels for Advanced 3D Cell Culture

Incorporating strain-stiffening and stress relaxation — engineered to replicate the dynamic mechanics of native ECM.

About Our Online GelMA

Risus suspendisse a orci penatibus a felis suscipit consectetur vestibulum sodales dui cum ultricies lacus interdum. Per suspendisse adipiscing a suspendisse auctor nibh a et at curae condimentum suspendisse enim a eu scelerisque.

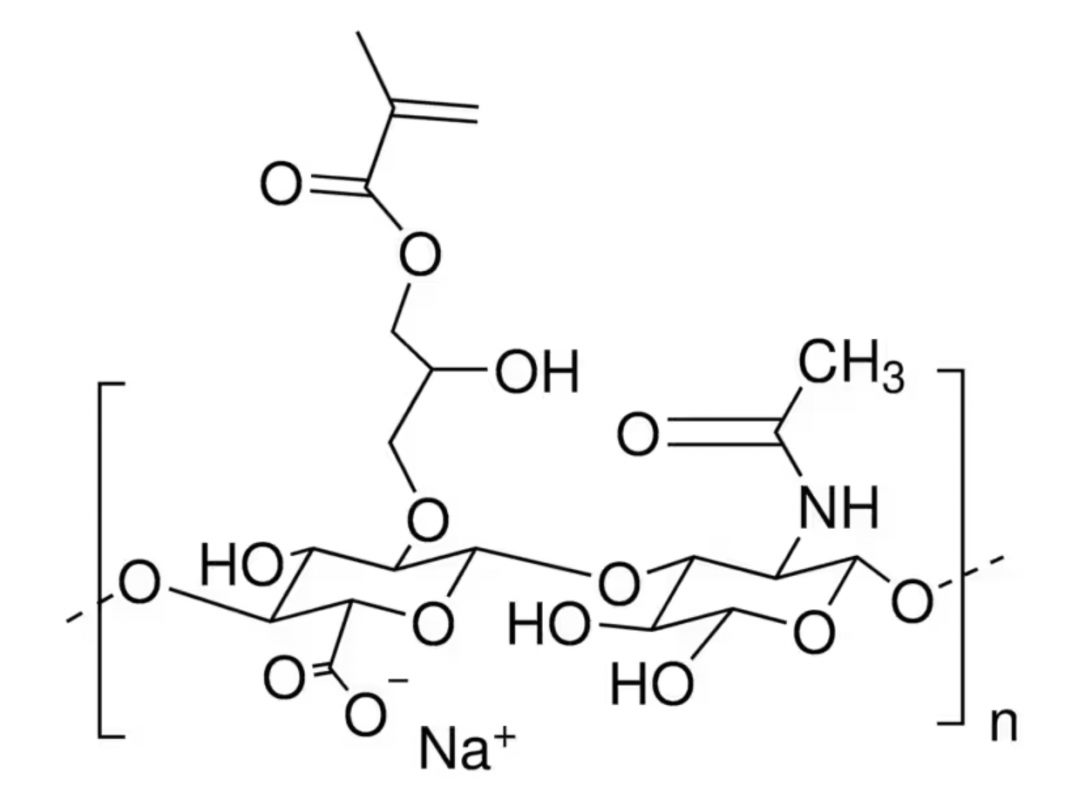

1. Optimized GelMA Synthesis

Gelatin methacryloyl (GelMA) is widely used in tissue engineering due to its intrinsic bioactivity and tunable mechanical properties. However, conventional synthesis methods often result in significant batch-to-batch variations in the degree of methacrylation (DoM),leading to inconsistent hydrogel mechanics. We have refined the GelMA synthesis process to achieve highly reproducible DoM control, reduced side reactions, and improved solubility. This ensures reliable hydrogel performance across different lots, thereby supporting both academic research and translational applications.2.Stress Relaxation Enables Dynamic culture Microenvironments

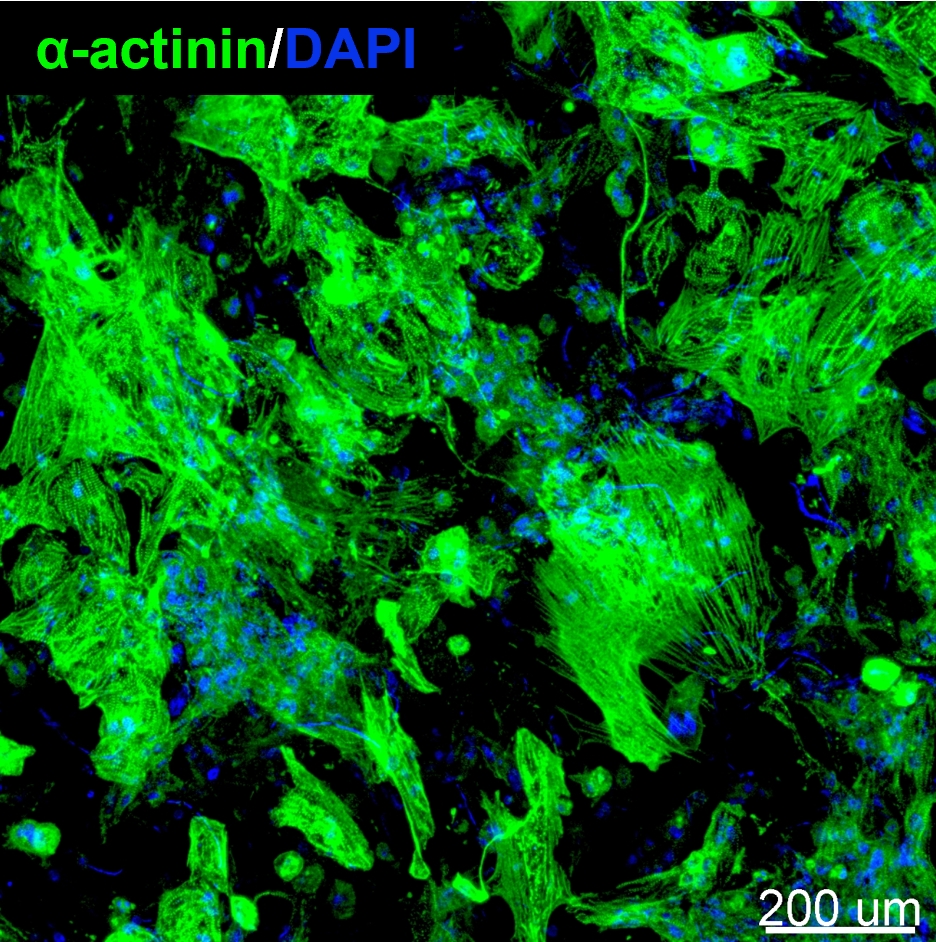

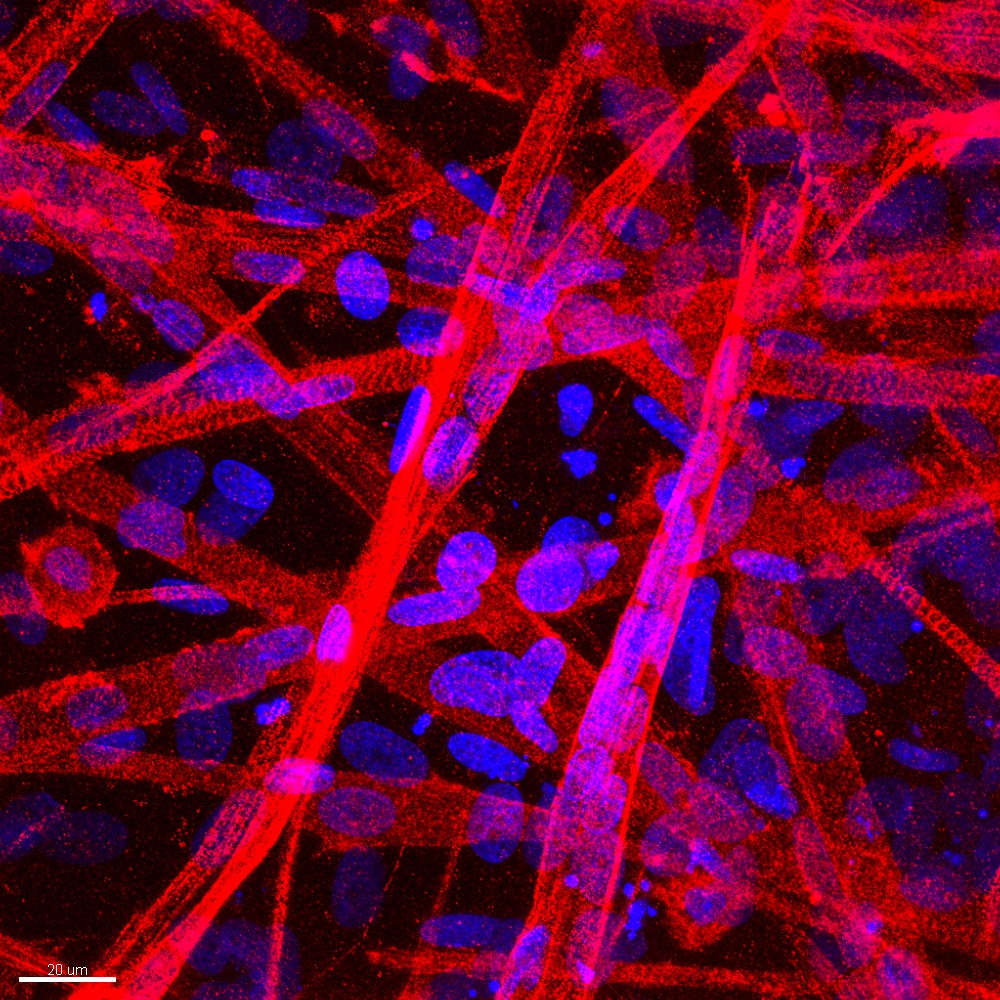

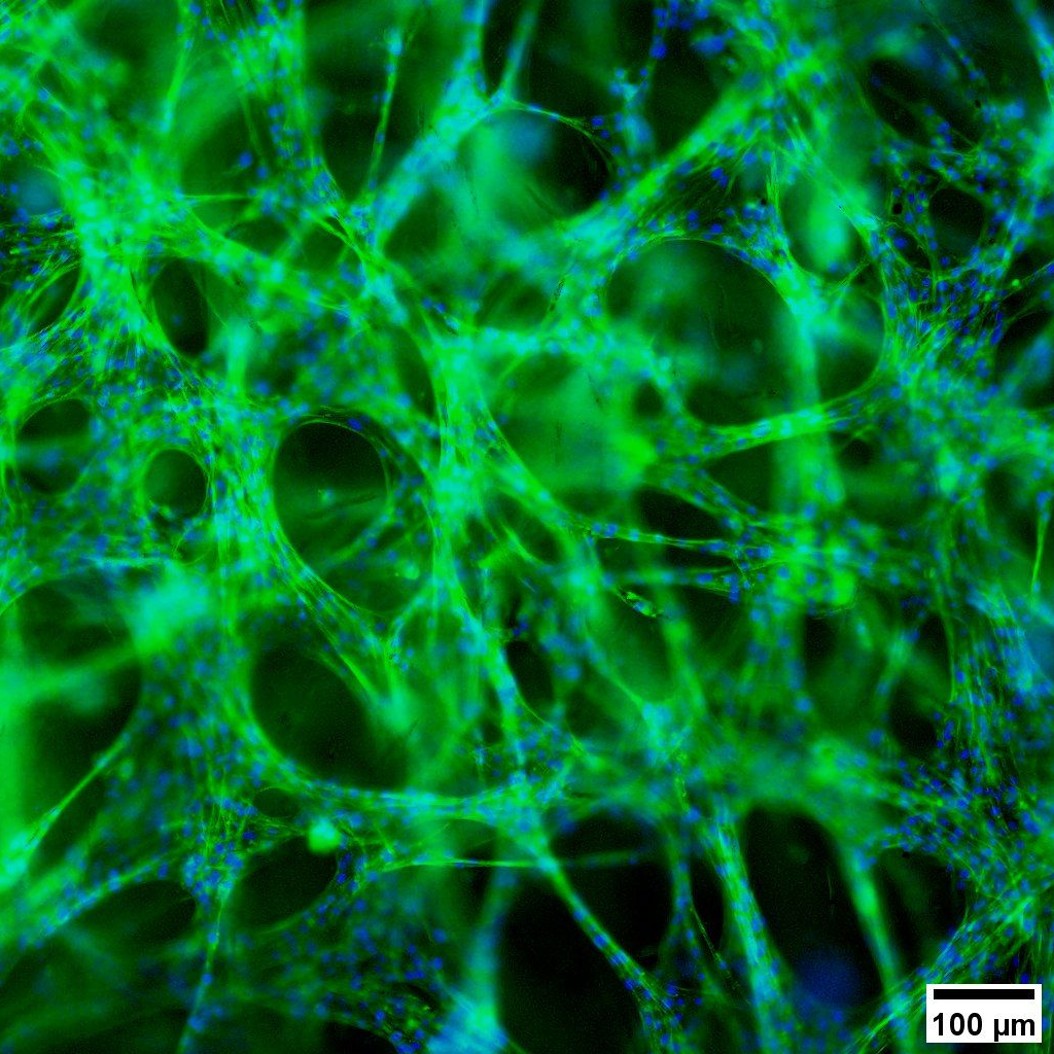

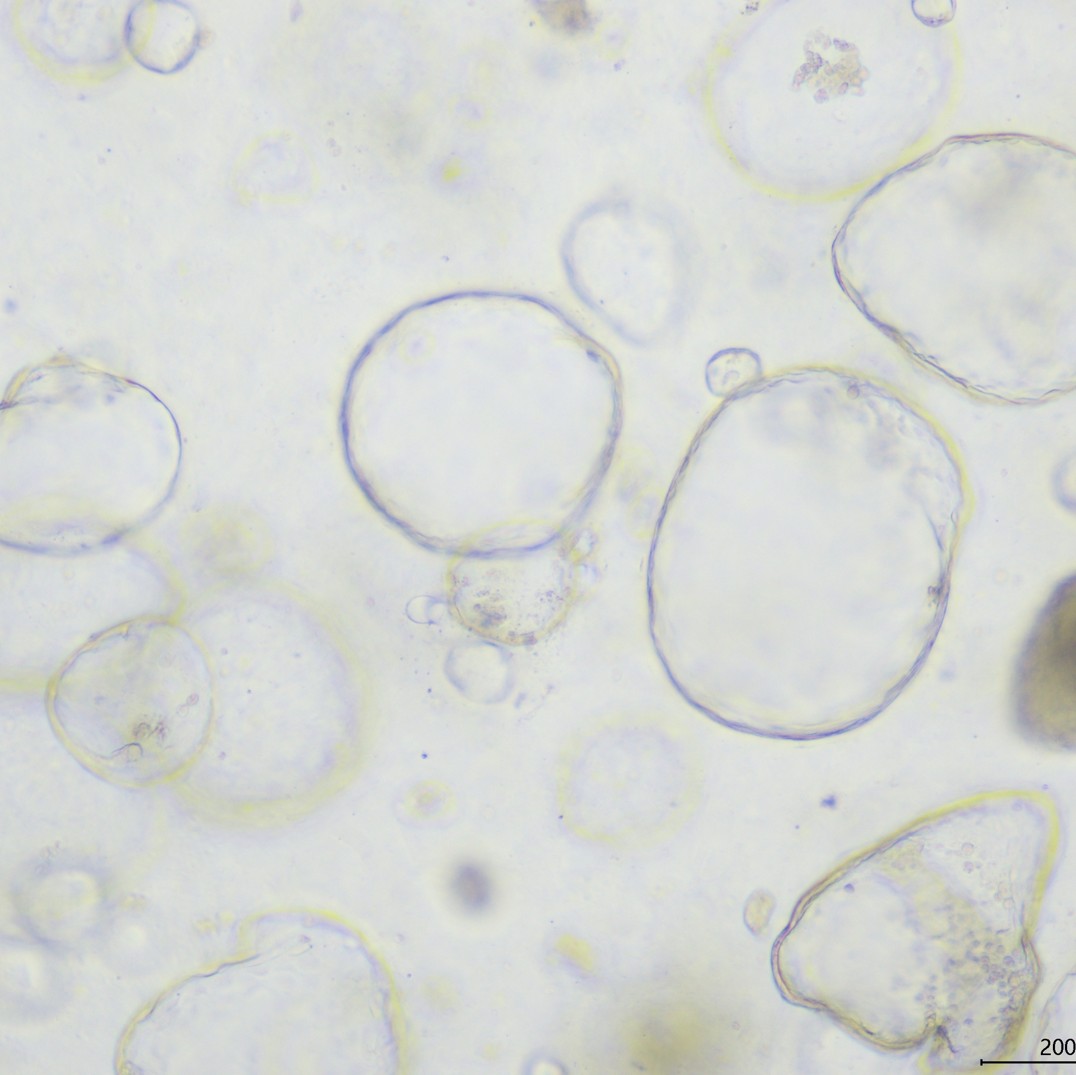

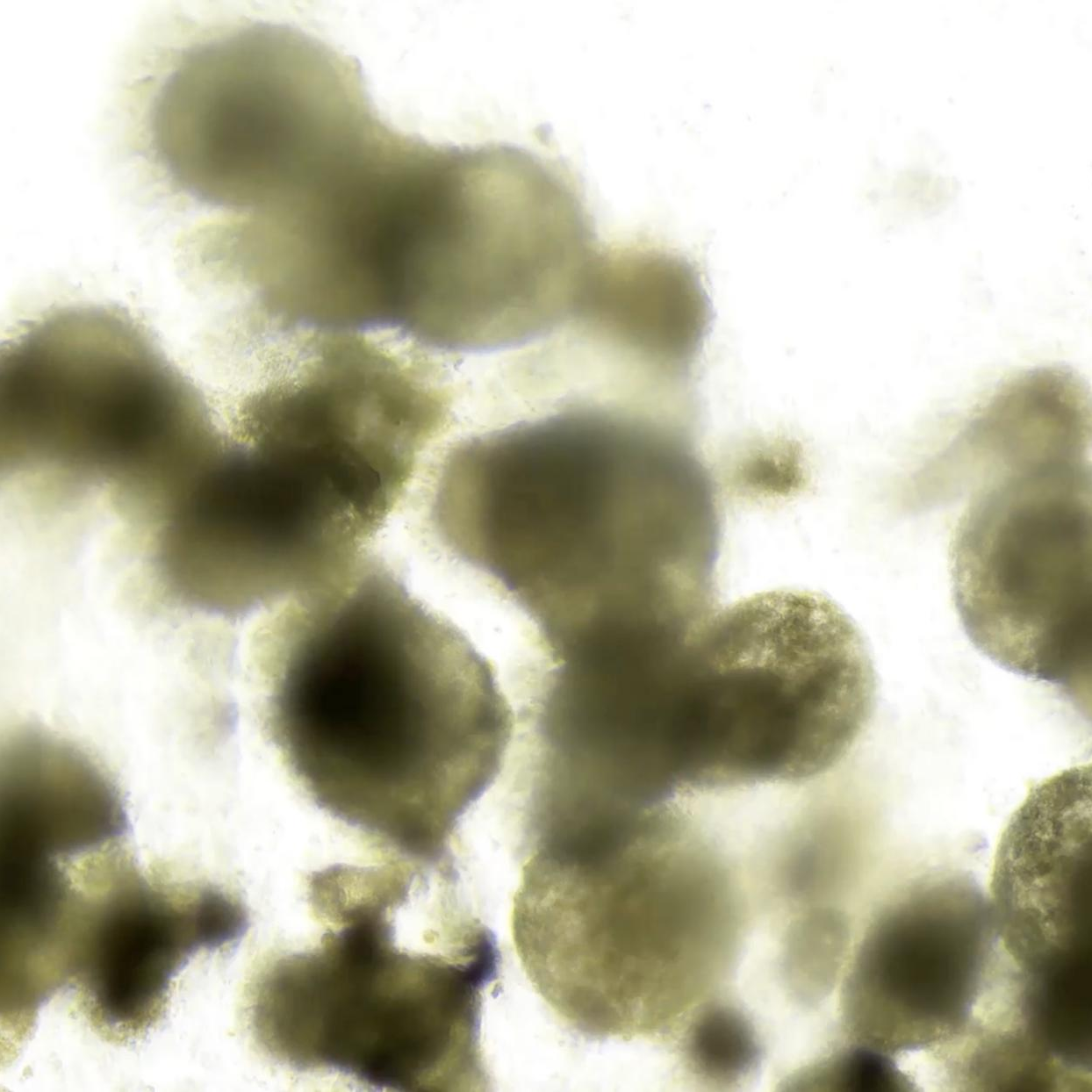

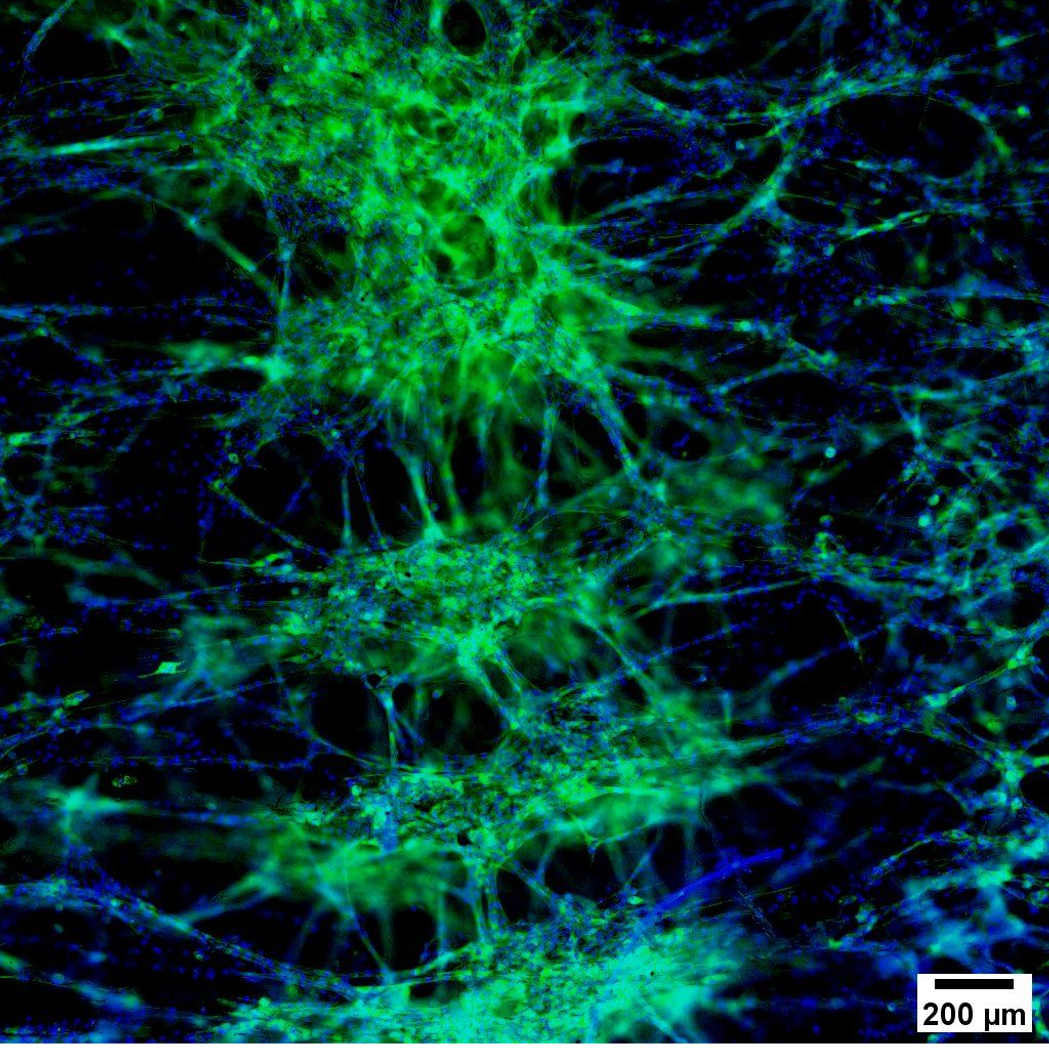

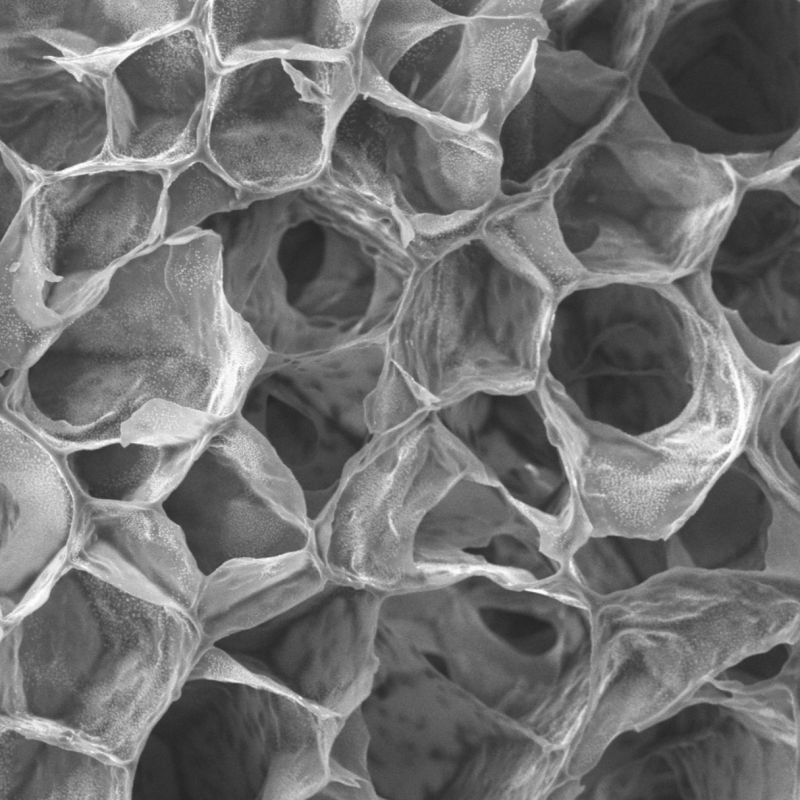

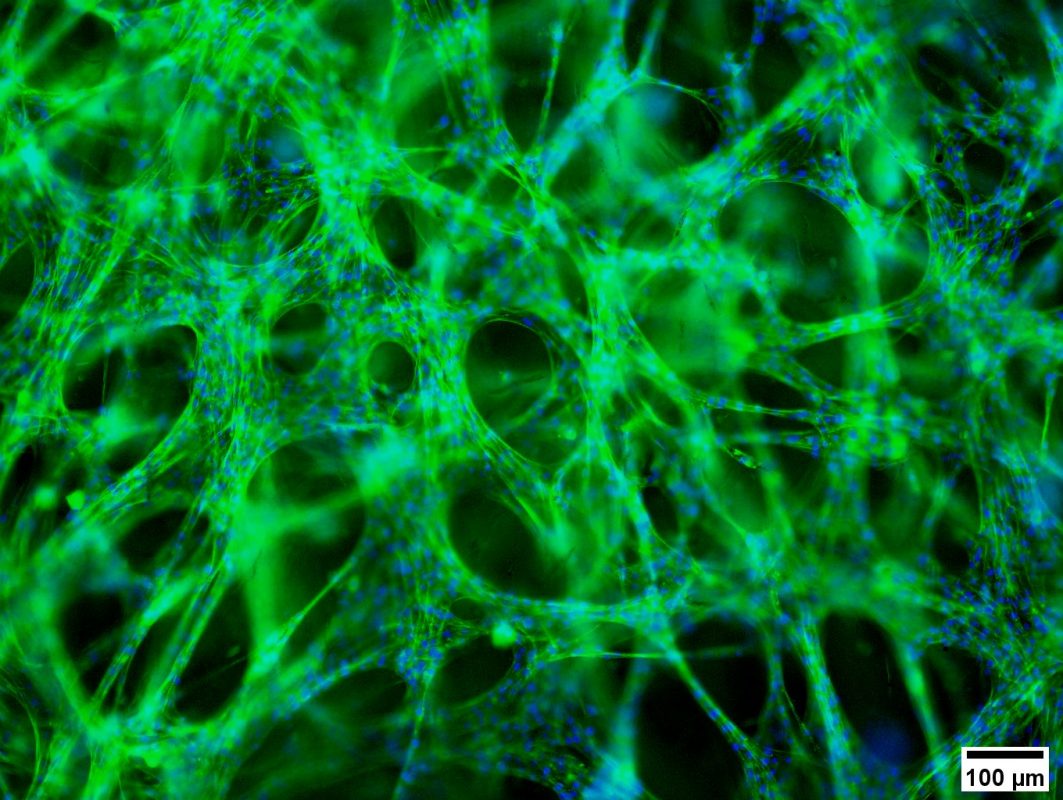

Native extracellular matrix (ECM) is not purely elastic, but viscoelastic, allowing time-dependent stress relaxation that profoundly affects cellular mechanotransduction. Recent studies (2020–2024) highlight that stress relaxation dynamics regulate stem cell fate, spreading, migration, and lineage-specific differentiation. Our GelMA hydrogels incorporate tunable viscoelasticity by adjusting crosslinking density and secondary network interactions, enabling hydrogels that better replicate the in vivo microenvironment. This provides cells with an adaptive and physiologically relevant matrix, enhancing reproducibility in organoid culture and disease modeling.3. Tunable Mechanics for Diverse Applications

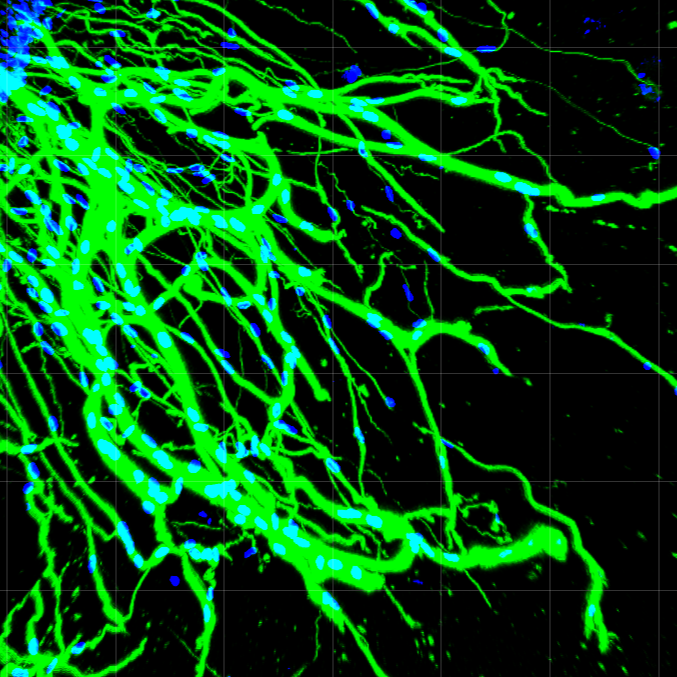

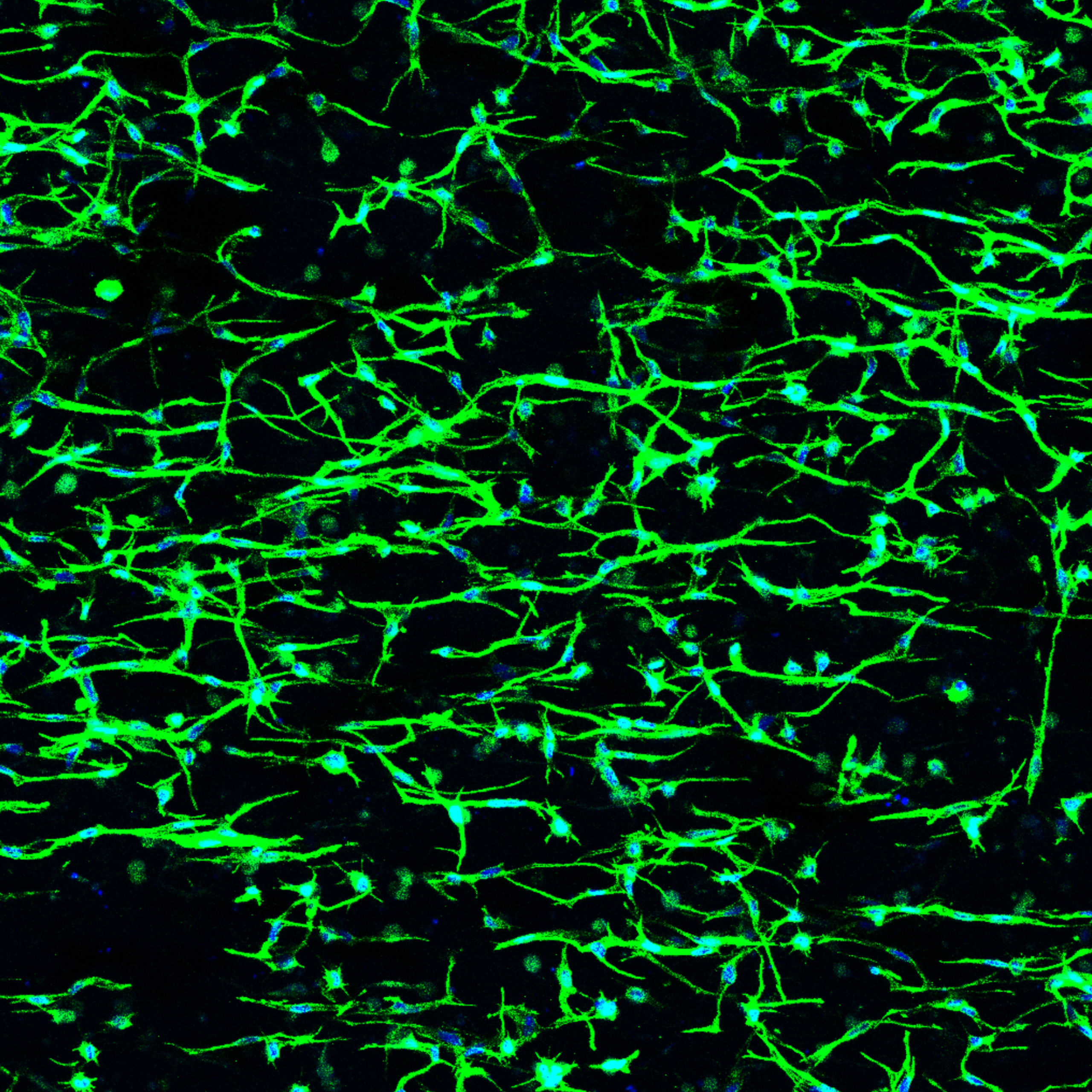

Different tissues demand distinct mechanical environments — neural tissue requires soft matrices (~0.5–1 kPa), while cartilage or bone models require stiffer hydrogels (>30–50 kPa). Our GelMA platform provides precise stiffness tuning through concentration control, photo-crosslinking conditions, and blending with other methacrylated polymers. This flexibility allows GelMA hydrogels to support a broad spectrum of applications, ranging from in vitro neural network studies, vascular models, to high-load musculoskeletal constructs. Furthermore, tunable degradation rates allow synchronization of matrix remodeling with cellular activity.4. Expanded Hydrogel Portfolio & Custom Synthesis

While GelMA is our flagship product, our portfolio extends to AlgMA, DexMA, HA-derivatives (HAD), FITC-GelMA, and Rhodamine-GelMA, providing options for functional imaging, drug delivery, and organ-on-a-chip applications. In addition, we offer custom hydrogel synthesis services, where clients can specify mechanical range, degradation profile, functional group density, and even fluorescent labeling. Through a one-to-one consultation process, we co-design hydrogels that precisely fit experimental and translational needs, ensuring high impact and reliability.References

- Yue, K., et al. (2015). Synthesis, properties and biomedical applications of gelatin methacryloyl (GelMA) hydrogels. Biomaterials, 73, 254–271.

- Loessner, D., et al. (2016). Functionalization, preparation and use of cell-laden GelMA hydrogels. Nature Protocols, 11, 727–746.

- Zhang, Y., et al. (2021). Engineering stress-relaxing hydrogels for stem cell fate modulation. Journal of Nanobiotechnology, 19, 157.

- Weber, J., et al. (2022). Viscoelastic hydrogels for 3D cell culture and tissue engineering. Frontiers in Soft Matter, 1, 879945.

- Benton, J., et al. (2009). Photocrosslinkable hydrogels for 3D cell culture. Adv. Funct. Mater., 19, 2132–2139.

- Shirahama, H., et al. (2016). Precise tuning of GelMA hydrogel stiffness for cell culture applications. Biomedical Materials, 11(3), 035004.

- Highley, C. B., et al. (2016). Modular and tunable bioink formulations for 3D bioprinting. Adv. Mater., 28, 5930–5936.

- Yue, K., et al. (2020). Bioactive hydrogels for advanced tissue engineering. Biomaterials, 257, 120264.

Our hydrogel products

GelMA (75% Substitution)

HAMA (Hyaluronic Acid Methacrylate) (25% substitution)

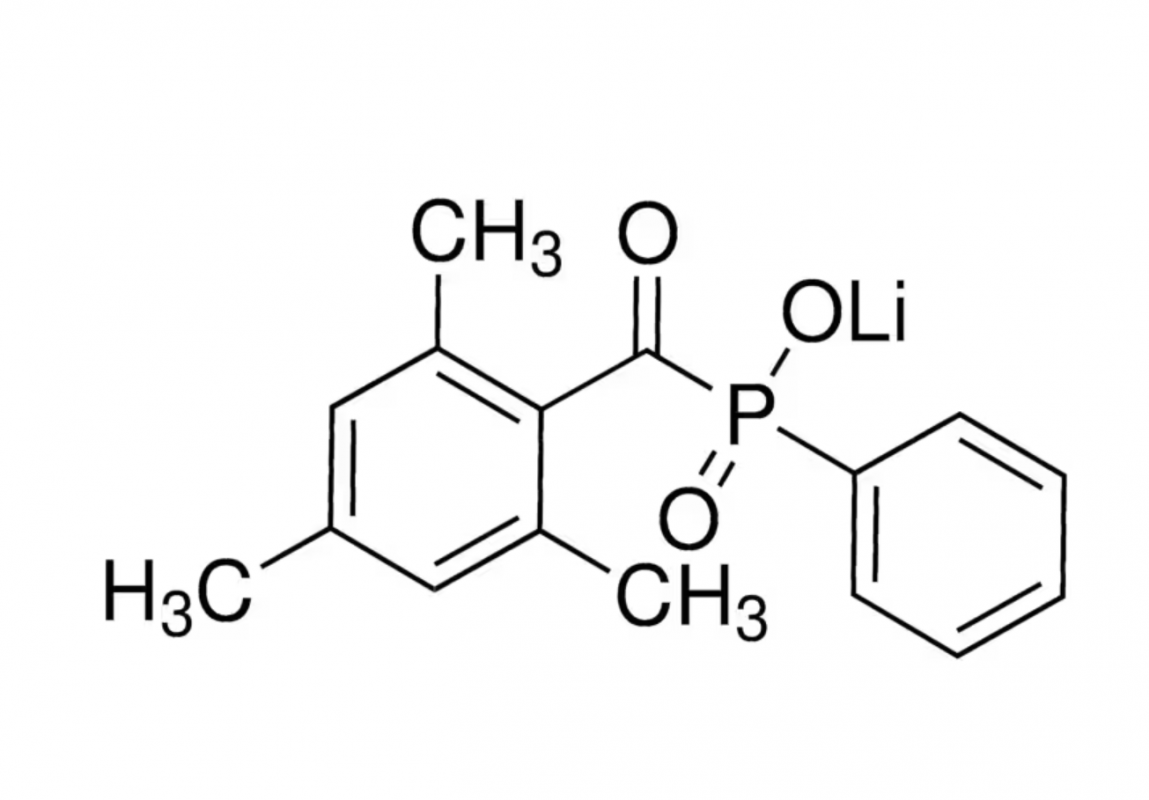

LAP

LAP (GMP grade)

Tailed Hydrogels for Your Research

We start with a one-to-one consultation to understand your specific research needs, including application scenarios and target cell types.

Key parameters such as mechanical stiffness, degree of methacrylation (DoM), fluorescence labeling (e.g., FITC, Rhodamine), and stress relaxation are defined and agreed with you.

Our team synthesizes hydrogels under optimized protocols, ensuring reproducibility, biocompatibility, and advanced functionalities such as stress-relaxation control.

Your tailored hydrogel is delivered ready to use. We provide validation data and support to ensure the material performs consistently in your experiments.