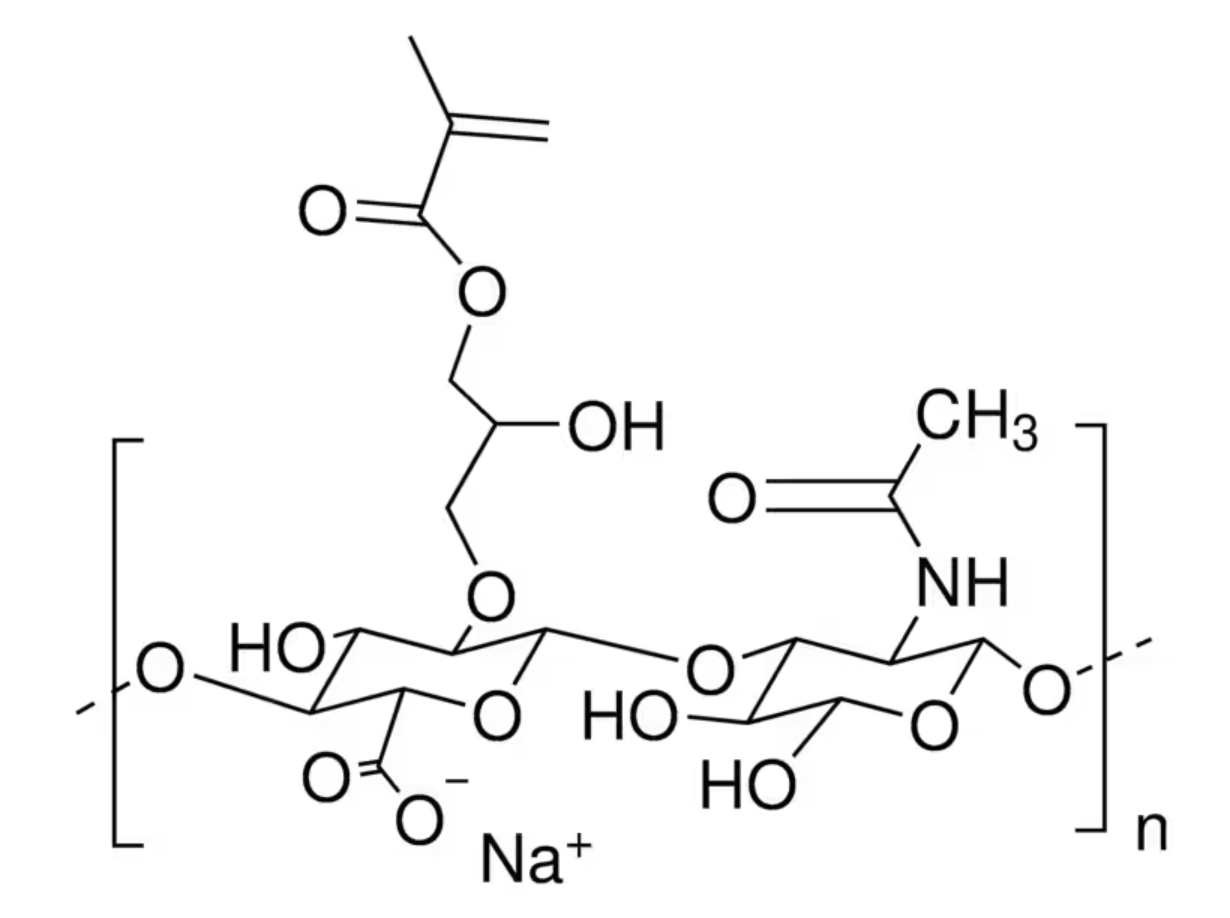

HAMA (Hyaluronic Acid Methacrylate) (25% substitution)

£110.00 – £2,200.00Price range: £110.00 through £2,200.00 excl. VAT

Description

HAMA (Hyaluronic Acid Methacrylate)

Biomimetic, green-chemistry–derived hydrogel precursor designed for tissue engineering and regenerative medicine research. Our HAMA is synthesized using an optimized, environmentally friendly process that reduces toxic by-products and ensures very low cytotoxicity. The resulting material offers excellent biocompatibility for sensitive cell types and robust performance in 3D culture applications. For research use only.

Key Features

- Green chemistry synthesis: sustainable production with reduced solvent and waste load.

- Low cytotoxicity: optimized methacrylation reaction eliminates residual toxic intermediates.

- High biocompatibility: supports viability of sensitive primary cells, stem cells, and organoids.

- Native ECM mimicry: preserves hyaluronic acid’s biological activity and hydration properties.

- Photocrosslinkable: compatible with LAP and Irgacure 2959 under 365–405 nm light.

Typical Applications

- 3D cell culture and encapsulation (primary cells, stem cells, tumor spheroids)

- Biofabrication and 3D bioprinting of ECM-like scaffolds

- Organoid and tissue model development

- Cartilage, neural, and vascular tissue engineering research

Specifications

| Property | Details |

|---|---|

| Product name | Hyaluronic Acid Methacrylate (HAMA) |

| Source | Sodium hyaluronate (bacterial fermentation, non-animal origin) |

| Form | Lyophilized powder |

| Appearance | White to off-white powder |

| Degree of substitution | ~10–20% (tunable, QC-verified) |

| Solubility | Water-soluble; dissolve in PBS or DI water |

| Photocrosslinking | 365–405 nm (with LAP or Irgacure 2959) |

| Endotoxin | Low endotoxin, QC-checked |

| Storage | Dry, protected from light |

| Shelf life | 12 months from receipt when stored properly |

| Research use | For research use only; not for human or clinical use |

Validated Systems

HAMA hydrogels have been successfully used for the 3D culture of hiPSCs, MSCs, neural stem cells, HUVECs, chondrocytes, and cancer organoids, demonstrating superior cell viability and matrix remodeling compared with conventional HAMA products.

Preparation & Use

- Dissolution: dissolve HAMA in sterile PBS or DI water (commonly 0.5–2% w/v).

- Photocrosslinking: crosslink under 365–405 nm light in the presence of LAP or other photoinitiators.

- Handling: prepare fresh working solutions, protect from light, and filter-sterilize if needed.

Safety

Use appropriate PPE when handling. Avoid inhalation or contact with skin and eyes. Dispose of waste according to local regulations. For research use only.

What’s Included

- HAMA powder in selected pack size (100 mg / 1 g / 10 g)

- Certificate of Analysis (CoA)

- Quick-start protocol